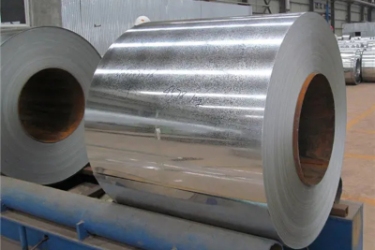

DX51D+AZ150 Z275 SGCC Galvanized GI Steel Coil

Product Details(Feature/Advantages)

Galvanized coil is produced by continuous hot-dip galvanizing process using hot-rolled steel strip or cold-rolled steel strip as substrate. Hot-dip galvanized sheets are supplied in rectangular flat sheets after cross-cutting; hot-dip galvanized coils are supplied in coils after coiling.

Galvanized steel coil is one of the hot-selling products of Delong Metal. It is available in big, regular, small, and zero spangles. Compared to color steel coil, it is more affordable. Hot-dip galvanized coils are mainly used in containers, home appliances, automobiles, transportation, home business, construction and other fields. Especially in automobile manufacturing, steel structure construction, steel silo manufacturing and other industries. Their main features are: good surface quality, strong corrosion resistance, benefit from deep processing, economical and practical, etc.

As a wholesale supplier, Delong Metal can meet bulk orders timely. Also, we will offer a direct-sale price to lower your cost. If you are interested, please contact us for details.

| SPECIFICATION PARAMETER | |

| Commodity | Galvanized Steel Coil |

| Grade | SGCC, SGCD, SGCE |

| DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z | |

| S250GD+Z,S280GD+Z, S350GD+Z,S550GD+Z | |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS |

| Zinc coated: | 30g/m2-275g/m2 |

| Spangle | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Surface treatment | Chromated, oiled/non-oiled and anti-finger printing |

| Thickness | 0.12-2.0mm |

| Width | 600-2,000mm |

| Coil Weight | 3 – 5 tons (can be customized) |

| Certificates | SGS, BV, ISO 9001 |

| Supply Ability | 40000MT/month |

| MOQ | 5MT |

| Package | Standard export package |

| Substrate | Hot rolled steel/Cold rolled steel |

| Tolerance | Thickness: 0.01 mm |

| Width: 2 mm | |

| ID | 508mm – 610mm |

| Trade Term | FOB, CFR, CIF |

| Payment terms | T/T, L/C at sight, West Union, D/P, D/A, Paypal |

| Delivery time | 7-14 days after confirmed order |

| Loading port | Tianjin port |

| Container size | 20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) |

| 40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) | |

| 40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High) | |

| STEEL GRADE | CHEMICAL COMPOSITION % | ||||

| C | Si | Mn | S | P | |

| x103 | x103 | x102 | x103 | x103 | |

| JIS G3302 SGCC | 12 | 30 | 41 | 31 | 21 |

| JIS G3302 SGCH | 12 | 10 | 21 | 18 | 8 |

| ASTM A653 CS.B | 29 | 30 | 60 | 35 | 30 |

| DX51D+Z | 20 | 21 | 18 | 1.8 | 11 |

| G550 | 12 | 6 | 73 | 5 | 17 |

| Material | Chinese Code | Japanese Code | European Code |

| Commercial Use | DX51D+Z/DC51D+Z (CR) | SGCC | DX51D+Z |

| Drawing Quality | DX52D+Z/DC52D+Z | SGCD1 | DX52D+Z |

| Deep Drawing Quality | DX53D+Z/DC53D+Z/DX54D+Z/DC54D+Z | SGCD2/SGCD3 | DX53D+Z/DX54D+Z |

| Structural Use | S220/250/280/320/350/550GD+Z | SGC340/400/440/490/570 | S220/250/280/320/350GD+Z |

| Commercial Use | DX51D+Z/DD51D+Z (HR) | SGHC | DX51D+Z |

| Surface treatment type | Code | Feature |

| Chromic acid treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Have certain corrosion resistance, good paint performance, and prevent rust |

| Oiled | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

| Galvanized Steel Coil Gauge Chart | ||

| Gauge | mm | Inches |

| 8 | 4.27 | 0.1681 |

| 9 | 3.89 | 0.1532 |

| 10 | 3.51 | 0.1382 |

| 11 | 3.13 | 0.1233 |

| 12 | 2.75 | 0.1084 |

| 14 | 1.99 | 0.0785 |

| 16 | 1.61 | 0.0635 |

| 18 | 1.31 | 0.0516 |

| 20 | 1.01 | 0.0396 |

| 21 | 0.93 | 0.0366 |

| 22 | 0.85 | 0.0336 |

| 23 | 0.78 | 0.0306 |

| 24 | 0.7 | 0.0276 |

| 25 | 0.63 | 0.0247 |

| 26 | 0.55 | 0.0217 |

| 27 | 0.51 | 0.0202 |

| 28 | 0.47 | 0.0187 |

| 30 | 0.4 | 0.0157 |

Spangle is formed during the hot-dip galvanizing process. The size, brightness, and surface of spangles mainly depend on the composition of the zinc layer and the cooling method. According to the size, it includes small spangles, regular spangles, big spangles, and free spangles. They look different, but the spangles almost will not

influence the quality of galvanized steel. You can choose according to your preference and use purpose.

(1) Big or Regular Spangles

Spangle-promoting elements are added to the zinc bath. Then beautiful spangles are formed as the zinc layer solidifies. It looks good. But the grains are coarse and there is slight unevenness. In a word, its adhesion is poor but weather resistance is good. It is most suitable for guardrail, blower, duct, rolling shutter, drain pipe, ceiling bracket, etc.

(2) Small Spangles

During the solidification process of the zinc layer, zinc grains are artificially restricted to form as fine spangles as possible. The spangle size can be controlled by cooling time. Generally, the shorter the cooling time, the smaller the size. Its coating performance is great. Therefore, it is perfect for drainage pipes, ceiling brackets, door columns, the substrate for color coated steel, car body panels, guardrails, blowers, etc.

(3) Zero Spangles

By adjusting the chemical composition of the bath, the coating has a uniform surface without visible spangles. The grains are very fine and smooth. It has excellent corrosion resistance and good coating performance. It is also ideal for drainage pipes, automobile components, back panels for home appliances, automobile body panels, guardrails, blowers, etc.

Galvanized coil features lightweight, aesthetics, and excellent corrosion resistance. It can be used directly or as the base metal for PPGI steel. Therefore, GI coil has been a new material for many fields, such as construction, shipbuilding, vehicle manufacturing, furniture, home appliances, etc.

1. Construction

They are often used as roofing sheets, interior and exterior wall panels, door panels and frames, the surface sheet of the balcony, ceiling, railings, partition walls, windows and doors, gutter, sound insulation wall, ventilation ducts, rainwater pipes, rolling shutters, agricultural warehouses, etc.

2. Home Appliances

GI coil is widely applied to home appliances, such as the back panel of air conditioners, and the outer casing of washing machines, water heaters, refrigerators, microwave ovens, switch cabinets, instrument cabinets, etc.

3. Transportation

It is mainly used as decorative panels for cars, corrosion-resistant parts for cars, decks of trains or ships, containers, road signs, isolation fences, ship bulkheads, etc.

4. Light Industry

It is ideal for making chimneys, kitchen utensils, garbage cans, paint buckets, etc. At Wanzhi Steel, we also make some galvanized products, such as chimney pipes, door panels, corrugated roofing sheets, floor decks, stove panels, etc.

5. Furniture, such as wardrobes, lockers, bookcases, lampshades, desks, beds, bookshelves, etc.

6. Other Uses, such as post and telecommunication cable, highway guardrails, billboards, newsstands, etc.