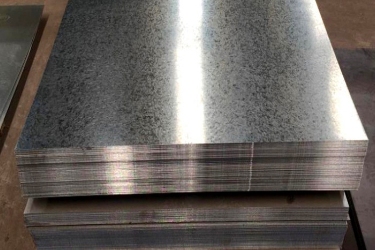

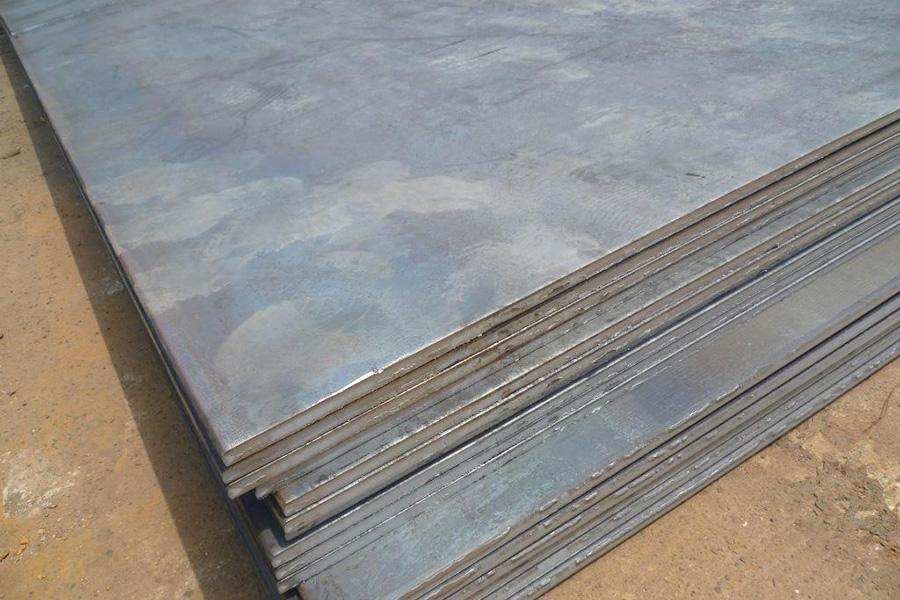

Z275 Galvanized Sheet gi steel plate 0.8mm Corrugated Steel Iron Zinc Coating Steel Sheet

Product Details(Feature/Advantages)

Delong Metal is group company in the steel manufacture & Trading, founded in the 2000s, 800+ staff, 25, 000+ m2 non-dust workshop, 40+ great large mills and cooperation partners in China, 4000, 000+ MT production per year under ISO management, 40, 000+customers in domestic and overseas market, 10 billion USD of annual turnover, 15+ subsidiary companies all over China, ranking the Top 100 private enterprises in China, 1 hour reach Shanghai/Tianjin /Guangzhou Port, we keep high quality, competitive price, thousands tons of stock, most efficient delivery and reliable cooperation for global valued customers. We have been engaging industry steel for over 20 years, best service and the most competitive price is one of our greatest advantages that make us today!

We operate within the scope of ISO 9001: 2015 accredited management system and the raw materials are procured from suppliers in compliance with ASTM, BS EN and DIN standards.Our products are rigorously inspected to ensure they are within tolerance of our customer′s specifications, we work with accredited laboratories for specialised material testing and chemical analysis.In addition, we use X-ray fluorescence technology to meet our high inspection standards and to ensure that our customers get the best quality products.

| Technical Standard | ASTM DIN GB JIS3302 |

| Grade | SGCC SGCD or Customer’s Requirement |

| Type | Commercial Quality/DQ |

| Thickness | 0.13mm-4.0mm |

| Width | 600mm-1500mm |

| Type of Coating | Hot Dipped Galvanized |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation/skin pass/non-oiled/oiled |

| Surface Structure | Zero Spangle / Mini Spangle / Regular Spangle / Big Spangle |

| ID | 508mm/610mm |

| Coil Weight | 3-10metric ton per coil |

| Package | Standard export package or customized |

| Hardness | HRB50-71 ( CQ Grade ) |

| HRB45-55 ( DQ Grade ) | |

| Yield Strength | 140-300 (DQ Grade) |

| Tensile Strength | 270-500 (CQ Grade) |

| 270-420 (DQ Grade) | |

| Elongation Percentage | 22 (CQ Grade thickness less 0.7mm) |

| 24 (DQ Grade thickness less 0.7mm) |

| GAUGE | steel | Galvanized steel | Stainless steel | aluminum | Electrical steel |

| (Ga.) | |||||

| in (mm) | in (mm) | in (mm) | in (mm) | in (mm) | |

| 3 | 0.2391 (6.07) | – | – | – | – |

| 4 | 0.2242 (5.69) | – | – | – | – |

| 6 | 0.1943 (4.94) | – | – | 0.162 (4.1) | – |

| 7 | 0.1793 (4.55) | – | 0.1875 (4.76) | 0.1443 (3.67) | – |

| 8 | 0.1644 (4.18) | 0.1681 (4.27) | 0.1719 (4.37) | 0.1285 (3.26) | – |

| 9 | 0.1495 (3.80) | 0.1532 (3.89) | 0.1563 (3.97) | 0.1144 (2.91) | – |

| 10 | 0.1345 (3.42) | 0.1382 (3.51) | 0.1406 (3.57) | 0.1019 (2.59) | – |

| 11 | 0.1196 (3.04) | 0.1233 (3.13) | 0.1250 (3.18) | 0.0907 (2.30) | – |

| 12 | 0.1046 (2.66) | 0.1084 (2.75) | 0.1094 (2.78) | 0.0808 (2.05) | – |

| 13 | 0.0897 (2.28) | 0.0934 (2.37) | 0.094 (2.4) | 0.072 (1.8) | – |

| 14 | 0.0747 (1.90) | 0.0785 (1.99) | 0.0781 (1.98) | 0.0641 (1.63) | – |

| 15 | 0.0673 (1.71) | 0.0710 (1.80) | 0.07 (1.8) | 0.057 (1.4) | – |

| 16 | 0.0598 (1.52) | 0.0635 (1.61) | 0.0625 (1.59) | 0.0508 (1.29) | – |

| 17 | 0.0538 (1.37) | 0.0575 (1.46) | 0.056 (1.4) | 0.045 (1.1) | – |

| 18 | 0.0478 (1.21) | 0.0516 (1.31) | 0.0500 (1.27) | 0.0403 (1.02) | – |

| 19 | 0.0418 (1.06) | 0.0456 (1.16) | 0.044 (1.1) | 0.036 (0.91) | – |

| 20 | 0.0359 (0.91) | 0.0396 (1.01) | 0.0375 (0.95) | 0.0320 (0.81) | – |

| 21 | 0.0329 (0.84) | 0.0366 (0.93) | 0.034 (0.86) | 0.028 (0.71) | – |

| 22 | 0.0299 (0.76) | 0.0336 (0.85) | 0.031 (0.79) | 0.025 (0.64) | 0.0310 (0.787) |

| 23 | 0.0269 (0.68) | 0.0306 (0.78) | 0.028 (0.71) | 0.023 (0.58) | 0.0280 (0.711) |

| 24 | 0.0239 (0.61) | 0.0276 (0.70) | 0.025 (0.64) | 0.02 (0.51) | 0.0250 (0.64) |

| 25 | 0.0209 (0.53) | 0.0247 (0.63) | 0.022 (0.56) | 0.018 (0.46) | 0.0197 (0.50) |

| 26 | 0.0179 (0.45) | 0.0217 (0.55) | 0.019 (0.48) | 0.017 (0.43) | 0.0185 (0.47) |

| 27 | 0.0164 (0.42) | 0.0202 (0.51) | 0.017 (0.43) | 0.014 (0.36) | – |

| 28 | 0.0149 (0.38) | 0.0187 (0.47) | 0.016 (0.41) | 0.0126 (0.32) | – |

| 29 | 0.0135 (0.34) | 0.0172 (0.44) | 0.014 (0.36) | 0.0113 (0.29) | 0.0140 (0.35) |

| 30 | 0.0120 (0.30) | 0.0157 (0.40) | 0.013 (0.33) | 0.0100 (0.25) | 0.011 (0.27) |

| 31 | 0.0105 (0.27) | 0.0142 (0.36) | 0.011 (0.28) | 0.0089 (0.23) | 0.0100 (0.25) |

| 32 | 0.0097 (0.25) | – | – | – | – |

| 33 | 0.0090 (0.23) | – | – | – | 0.009 (0.23) |

| 34 | 0.0082 (0.21) | – | – | – | – |

| 35 | 0.0075 (0.19) | – | – | – | – |

| 36 | 0.0067 (0.17) | – | – | – | 0.007 (0.18) |

| 37 | 0.0064 (0.16) | – | – | – | – |

| 38 | 0.0060 (0.15) | – | – | – | 0.005 (0.127) |

Spangles:

Galvanized Coating Layer:

Process:

The annual capacity of Galvanized Line is 320,000 tons. We adopt the UEC hot dip galvanizing process which is the most advanced and wildly used in the world. The main specification of product is 0.15~1.5mm X 800~1250mm.

We could manufacture high performance GI with high zinc coating, non-spangle, minium spangle, regular spangle or big spangle along with the advanced processing of oiled and skin-passed. The product can be used in building materials and electrical appliance.

Application:

Packing & Delivery:

- 4 eye bands and 4 circumferential bands in steel

- Galvanized metal fluted rings on inner and outer edges

- Galvanized metal and waterproof paper wall protection disk

- Galvanized metal and waterproof paper around circumference and bore protection

- About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.