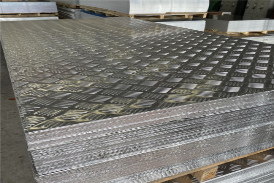

Aluminum checker plate/sheet

Product Details(Feature/Advantages)

Product Description

Aluminum Checker Plate/sheet

Please contact us for materials not mentioned below

| Specification of Aluminium Sheet | ||||

| Alloy No. | Thickness(mm) | Width(mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-1900 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-1700 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

| Packing : Export wooden pallets, wooden case | ||||

| Surface Treatment: Mill Finished, Anodized, PVC Coated,embossed,Stuccocheckered,diamond, sand blast ,bright, polished,hair line,brush,etc | ||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006,etc | ||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage,camber, dents, holes, break lines, scratches and free from coil set | ||||

| MOQ | 1 tons | |||

| Payment term: | TT,L/C,D/P, West Union,etc | |||

| Delivery Time | Future goods:20-30 Work days,Ready Stock:7-10 days. | |||

| Kind attention : Specifications can be customized as the customer’s requirements. | ||||

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | – | – | 0.05 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | – | – | 0.04 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | – | – | 0.1 | – | 99 | |

| 1200 | Si+Fe:1 | 0.05 | 0.05 | – | – | 0.1 | 0.05 | 99 | |

| 1235 | Si+Fe:0.65 | 0.05 | 0.05 | 0.05 | – | 0.1 | 0.05 | 99.35 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | – | – | – | 0.1 | remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-0.13 | – | – | 0.25 | remains |

| 3005 | 0.6 | 0.7 | 0.25 | 1.0-1.5 | 0.20-0.6 | 0.1 | – | 0.25 | remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.8 | 0.20-0.8 | 0.2 | – | 0.4 | remains |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | – | – | 0.1 | remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | – | 0.25 | remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | – | 0.1 | remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | – | 0.25 | remains |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | – | 0.2 | remains |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.1 | – | 0.25 | remains |

| 5251 | 0.4 | 0.5 | 0.15 | 0.1-0.5 | 1.7-2.4 | 0.15 | – | 0.15 | remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | – | 0.2 | remains |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | – | 0.25 | remains |

| 6063 | 0.20-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | – | 0.1 | remains |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.40-1.0 | 0.6-1.2 | 0.25 | – | 0.2 | remains |

As outlined below, the first digit indicates the alloy group according to the major alloying elements. 1xxx Series In this group minimum aluminum content is 99% and there is no major alloying element. The second digit indicates modifications in impurity limits. If the second digit is zero, there is no special control on individual impurities. Digits 1 through 9, which are assigned consecutively as needed, indicate special control of one or more individual impurities. The last two digits indicate specific minimum aluminum content. Although the absolute minimum aluminum content in this group is 99%, the minimum for certain grades is higher than 99%, and the last two digits represent the hundredths of a per cent over 99. Thus, 1030 would indicate 99.30% minimum aluminum. without special control on individual impurities. The designations 1130, 1230, 1330, etc.. indicate the same purity with special control on one or more impurities. Likewise 1100 indicates minimum aluminum content of 99.00% with individual impurity control. 2xxx through 9xxx Series The major alloying elements are indicated by the first digit, as follows: 2xxx Copper 3xxx Manganese 4xxx Silicon 5xxx Magnesium 6xxx Magnesium and silicon 7xxx Zinc 8xxx Other element 9xxx Unused series The second digit indicates alloy modification. If the second digit is zero. it indicates the original alloy: digits 1 through 9, which are assigned consecutively, indicate alloy modifications. The last two digits have no special significance, serving only to identify the different alloys in the group. Experimental Alloys Experimental alloys are designated according to the four digit system, but they are prefixed by the letter X. The prefix is dropped when the alloy becomes standard. During development, and before they are designated as experimental, new alloys are identified by serial numbers assigned by their originators. Use of the serial number is discontinued when the X number is assigned.

| Mechanical Property | ||||||||

|

ALUMINUM ALLOY |

Grade |

Normal Temper |

Temper |

Tensile Strength N/mm² |

Yield Strength N/mm² |

Elongation% |

Brinell Hardness HB |

|

| Plate | Bar | |||||||

| 1XXX | 1050 | O,H112,H | O | 78 | 34 | 40 | – | 20 |

| 1060 | O,H112,H | O | 70 | 30 | 43 | – | 19 | |

|

Al-Cu (2XXX) |

2019 | O,T3,T4,T6,T8 | T851 | 450 | 350 | 10 | – | – |

| 2024 | O,T4 | T4 | 470 | 325 | 20 | 17 | 120 | |

|

Al-Mn (3XXX) |

3003 | O | 110 | 40 | 30 | 37 | 28 | |

| 3004 | O,H112,H | O | 180 | 70 | 20 | 22 | 45 | |

| Al-Si (4XXX) | 4032 | O,T6,T62 | T6 | 380 | 315 | – | 9 | 120 |

|

Al-Mg (5XXX) |

5052 | O,H112,H | H34 | 260 | 215 | 10 | 12 | 68 |

| 5083 | O,H112,H | O | 290 | 145 | – | 20 | – | |

|

Al-Mg-Si (6XXX) |

6061 | O,T4,T6,T8 | T6 | 310 | 275 | 12 | 15 | 95 |

| 6063 | O,T1,T5,T6,T8 | T5 | 185 | 145 | 12 | – | 60 | |

|

Al-Zn-Mg (7XXX) |

7003 | T5 | T5 | 315 | 255 | 15 | – | 85 |

| 7075 | O,T6 | T6 | 570 | 505 | 11 | 9 | 150 | |

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||