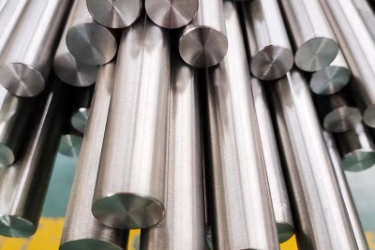

Nickel Bar

Product Details(Feature/Advantages)

Delong Metal is group company in the steel manufacture & Trading, founded in the 2000s, 800+ staff, 25, 000+ m2 non-dust workshop, 40+ great large mills and cooperation partners in China, 4000, 000+ MT production per year under ISO management, 40, 000+customers in domestic and overseas market, 10 billion USD of annual turnover, 15+ subsidiary companies all over China, ranking the Top 100 private enterprises in China, 1 hour reach Shanghai/Tianjin /Guangzhou Port, we keep high quality, competitive price, thousands tons of stock, most efficient delivery and reliable cooperation for global valued customers.

About price: Our business principle is to provide customers with the best competitive price on the premise of ensuring the quality of products.

If you need to know the preparation price and chemical composition of the product, please send us an inquiry.

Our email address: sale@sddlmetal.com

Whatsapp/ Wechat/ Skype: +86-13301536988

In addition to iron, carbon and a small amount of unavoidable silicon, manganese, phosphorus, and sulfur elements, steel also contains a certain amount of alloying elements. The alloying elements in steel include one or more of silicon, manganese, molybdenum, nickel, alum, alum, titanium, niobium, boron, lead, rare earth, etc. This kind of steel is called special alloy steel.Nickel-based alloy is a kind of special alloy steel. This page mainly introduces the basic information of nickel bar.

|

The grade, condition and specification of nickel bar |

|||

|

Grade |

State |

Diameter/mm |

Length/mm |

|

Incoloy 800 Incoloy 825 Inconel 600 Hastelloy C Hastelloy c276 Inconel 625 Hastelloy c22 Hastelloy X Nickel 200 Nickel 201 Monel 400 Monel K500 |

Y (hard) Y2 (semi-hard) M (soft) |

3~65 |

300~6000 |

|

R (thermal processing) |

6~254 |

||

|

Note: Bars with other specifications can be supplied after negotiation between the two parties, and the specific requirements should be specified in the contract. |

|||

|

Chemical Composition of Nickel Bar |

||||||||||||

|

Category |

Grade |

Chemical composition (mass fraction) % |

||||||||||

|

Ni+Co |

Cu |

Si |

Mn |

C |

S |

Fe |

Sb |

Zn |

Cd |

Sn |

||

|

pure nickel |

N5 (N02201) |

99.0 |

0.25 |

0.35 |

0.35 |

0.02 |

0.01 |

0.40 |

|

|

|

|

|

N7 (N02200) |

99.0 |

0.25 |

0.35 |

0.35 |

0.15 |

0.01 |

0.40 |

|

|

|

|

|

|

Nickel-copper series |

NCu30 (N04400) |

63.0 |

28.0~34.0 |

0.5 |

2.0 |

0.3 |

0.024 |

2.5 |

|

|

|

|

|

NCu30-3-0.5 (N05500) |

63.0 |

27.0~33.0 |

0.5 |

1.5 |

0.18 |

0.010 |

2.0 |

Al:2.30~3.15 |

Ti:0.35~0.86 |

|||

|

Diameter of cold-worked nickel bar and its allowable deviation |

||

|

Diameter |

Allowable deviation |

|

|

High precision |

Ordinary |

|

|

3~6 |

0.03 |

0.05 |

|

>6~10 |

0.04 |

0.06 |

|

>10~18 |

0.05 |

0.08 |

|

>18~30 |

0.06 |

0.10 |

|

>30~50 |

0.09 |

0.13 |

|

>50~65 |

0.12 |

0.16 |

|

Note: When the one-way deviation is required, its value is twice the value in the table; when the diameter of the nickel bar is required to be the allowable deviation of high-precision grade, it should be specified in the contract, otherwise it will be supplied as ordinary grade. |

||

|

Diameter of hot-worked nickel bar and its allowable deviation |

|||||

|

Diameter |

Extrusion |

Hot rolled |

Forging |

||

|

High precision(±) |

Ordinary(±) |

+ |

– |

||

|

6~15 |

0.60 |

0.80 |

0.60 |

0.50 |

±1.00 |

|

>15~30 |

0.75 |

1.00 |

0.70 |

0.50 |

±1.50 |

|

>30~50 |

1.00 |

1.20 |

1.50 |

1.00 |

±2.00 |

|

>50~80 |

1.20 |

1.55 |

2.00 |

1.00 |

±3.00 |

|

>80~120 |

1.55 |

2.00 |

2.20 |

1.20 |

±3.50 |

|

>120~160 |

– |

– |

– |

– |

±5.00 |

|

>120~200 |

– |

– |

– |

– |

±6.50 |

|

>200~254 |

– |

– |

– |

– |

±7.00 |

|

Note: When the one-way deviation is required, its value is twice the value in the table; when the diameter of the nickel bar is required to be the allowable deviation of high-precision grade, it should be specified in the contract, otherwise it will be supplied as ordinary grade. |

|||||

|

Straightness of nickel bar |

||||

|

Length |

Diameter≤20 |

Diameter > 20 |

||

|

full length straightness |

Straightness per meter |

full length straightness |

Straightness per meter |

|

|

<1000 |

≤3 |

– |

≤5 |

– |

|

≥1000~2000 |

≤3×Length(m)/1m |

≤3 |

≤5×Length(m)/1m |

≤5 |

|

>2000~6000 |

≤4×Length(m)/1m |

≤4 |

≤6×Length(m)/1m |

≤6 |

|

Note: Except for soft nickel bars. |

||||

|

Mechanical properties of nickel bars |

||||

|

Grade |

State |

Diameter/mm |

Tensile strength Rm/(N/mm2) |

Elongation A/% |

|

≥ |

||||

|

N5(N02201) N7(N02200) |

Y |

3~20 |

590 |

5 |

|

>20~30 |

540 |

6 |

||

|

>30~65 |

510 |

9 |

||

|

M |

3~30 |

380 |

34 |

|

|

>30~65 |

345 |

34 |

||

|

R |

32~60 |

345 |

25 |

|

|

>60~254 |

345 |

20 |

||

|

NCu30-3-0.5(N05500) |

Y |

3~20 |

1000 |

15 |

|

>20~40 |

965 |

17 |

||

|

>40~65 |

930 |

20 |

||

|

R |

6~254 |

Measured |

Measured |

|

|

M |

3~65 |

895 |

20 |

|

|

NCu30(N04400) |

R |

76~152 |

550 |

30 |

|

>152~254 |

515 |

30 |

||

|

M |

3~65 |

480 |

35 |

|

|

Y |

3~15 |

700 |

8 |

|

|

Y2 |

3~15 |

580 |

10 |

|

|

>15~30 |

600 |

20 |

||

|

>30~65 |

580 |

20 |

||

Applications:

- Incoloy 800 has good resistance to oxidative medium corrosion and high temperature carburization resistance. Incoloy 800 is used in chemical, petrochemical and food processing, nuclear engineering, as heat exchanger and steam generator tubes, synthetic fiber heating tubes and electric heating element sheaths.

- Incoloy 825 is resistant to oxide stress corrosion and oxidation-reduction composite medium corrosion. Incoloy 825 is suitable for heat exchangers and condensers, sulfuric acid environments containing various ions; composite pipe linings for oil and gas gathering and transportation pipelines; high-pressure air coolers.

- Inconel 600 can resist high temperature oxide medium corrosion, stress corrosion resistance and alkali corrosion resistance. Inconel 600 is suitable for heat treatment and chemical processing industrial installations, nuclear power and automotive engineering.

- Hastelloy C is corrosion-resistant to chlorine and its compounds, and is suitable for applications in highly corrosive oxidation-reduction composite media and high-temperature seawater.

- Hastelloy c276 is resistant to oxidative chloride aqueous solution, wet chlorine and hypochlorite corrosion. Hastelloy c276 strong corrosive oxidation-reduction composite medium and welding components in high temperature seawater, nuclear power main pump motor shielding sleeve, flue gas desulfurization equipment.

- Inconel 625 is resistant to oxidation-reduction composite media, seawater corrosion, crevice corrosion and high thermal strength, high temperature oxidation resistance. Inconel 625 is suitable for use in industries such as aerospace engineering, gas turbines, chemical processing, oil and gas extraction, pollution control, marine and nuclear engineering.

- Hastelloy c22 is resistant to corrosion by oxidizing solutions containing chloride ions. Hastelloy c22 is suitable for acetic acid, phosphoric acid manufacturing, nuclear fuel recovery, heat exchangers, surfacing valves.

- Hastelloy X has the characteristics of excellent resistance to high temperature oxidation and excellent high temperature durable creep. Hastelloy X is suitable for use in aeronautical, marine and land-based gas turbine engine burners and other manufacturing components, electrical for heat treatment and nuclear engineering.

-

Both Nickel 200 and Nickel 201 have good mechanical properties and corrosion resistance, and are used in caustic soda and synthetic fibers and food processing.

Monel 400 has high strength and excellent resistance to seawater medium, acid and alkali properties of dilute hydrofluoric acid and sulfuric acid. Monel 400 is used in marine and marine engineering, salt production, feed water heater tubes, chemical and oil and gas processing. - Monel K500 has higher strength and excellent resistance to seawater medium, acid and alkali properties of dilute hydrofluoric acid and sulfuric acid. Monel K500 is used in pump shafts, oil well tools, scrapers, springs, fasteners and ship propeller shafts.